|

Home > Case Study

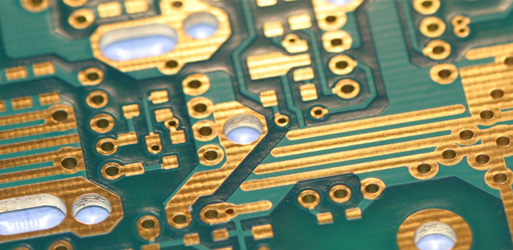

Case StudyPrinted Circuit BoardA PCB manufacturer comes to ASMAC with a PCB plated with a typical immersion gold layer on an underneath nickel layer. The manufacturer complains that some area of the gold plating surface has a reddish color and wants to know if this is kind of organic contamination.

Upon knowing that our client suspects the cause of color change to be foreign organic contamination on the plating surface, our staff inspects the sample surface using a stereo-microscope. From the enlarged surface image, we observe that the stained region is small, and it is not really possible to do any solvent extraction for chemical analysis to determine its nature. We therefore suggest to our client that we can proceed with Fourier Transform Infrared Microscopy (FTIR) study in Attenuated Total Reflection (ATR) Mode; which is an easy and inexpensive way of screening organic matters even on tiny surfaces. Should there be organic signal feedback, it would be magnified for post-analysis. Having obtained the consensus of the client, we perform the FTIR analysis. However, the testing result is negative, which means there are no meaningful organic signals from the gold plating surface. Having ruled out the possibility of major organic contamination, we suggest that our client look at the chemical depth profile of the stained region so as to determine whether trace amount of organic elements do exist, and to figure out what other elemental factors are in fact playing a part. To achieve this, we advise the use of X-ray Photoelectron Spectroscopy (XPS) which is equipped with an ion sputter gun to remove the plating layer by layer. By XPS, we can determine the composition as well as the chemical states of the elements-of-interest in each fresh layer obtained after each sputter cycle. Having the compositional and chemical information on the plating, we are likely to be able to judge if this is kind of corrosion, black nickel case or foreign object attachment. We set up an XPS depth profiling analysis procedure after receiving the essential background information such as plating layer thickness specifications from the client. The final results reveal that sulphur is detected at the top 20 nanometer of the gold plating, which is not supposed to exist in proper conditions. Abnormal high carbon content is also observed at the gold surface. Our client believes this is somehow the cause of the stain on the gold plating and requests ASMAC to summarize the findings in a test report such that it can be passed to the production line colleagues for follow-up actions. |